Our booth at Power2Drive is ready! If you want to drop by spontaneously, send us an email — we still have free tickets available.

Blog

Booth at Power2Drive

Olaf Lüke - 2 months, 1 week ago

Tinkerforge with WARP at Power2Drive Exhibition in Munich

Bastian Nordmeyer - 2 months, 3 weeks ago

From May 7 to May 9, 2025, we will be showcasing our brand WARP at the Power2Drive Europe trade fair in Munich.

This trade fair is one of the largest events for charging infrastructure and electromobility, and takes place alongside Intersolar. You can find us in Hall C6, on the outer side facing Hall C5 (Booth C6.173). At our booth, we’ll be presenting various versions of the WARP3 Charger, our WARP stand and the new WARP Energy Manager 2.0. Animated display boards will explain how to use solar power in combination with dynamic electricity pricing, charging electric vehicles, controlling heat pumps and controlling battery storage systems. Our dynamic load management will also be featured.

We’re looking forward to your visit!

An overview of the developments of the last 6 months

Bastian Nordmeyer - 4 months, 4 weeks ago

For a long time, it has been quiet here on this blog... However, a lot has happened since the last post in August 2024. Most of the news concerns our WARP3 Chargers. A total of eleven software updates have been released for the WARP3 Charger since then, introducing the following new features:

Release of Remote Access

With this feature, access to the local web interface of the wallbox via the internet through my.warp-charger.com is possible. Unlike other solutions, communication does not go through the "cloud." Instead, communication happens directly between the browser and the wallbox. More information on this can be found on Tinkerunity. In the latest version, up to five remote access users are possible.

iOS and Android Apps

The apps for iOS and Android have been available in beta since the end of last year. Technically, the apps use our remote access. Anyone who wants to participate in testing is welcome to do so. The description for this can be found in the forum. For everyone else, it shouldn’t take too long until we officially release the apps in the respective stores.

Dynamic Load Management

We really didn’t make it easy for ourselves when developing the dynamic load management system. That’s why we are even prouder of the result! In the latest version, the load management supports a network of up to 64 wallboxes, considering fairness (all vehicles will be charged), minimizing switching operations, phase rotations, the charging behavior of vehicles (1ph vs. 3ph, etc.), and much more.

PV Surplus Charging

Now more than one wallbox is supported. If a battery storage system is available and can be read, it is incorporated into the regulation.

Expansion of Compatible Electricity Meters/Inverters

We try to make our devices compatible with as many third-party devices as possible. The idea behind this is that the wallbox can access already existing electricity meters, PV inverters, or battery storage systems. Fortunately, many manufacturers offer standardized interfaces like SunSpec or Modbus TCP. Unfortunately, experience has shown that the effort is much greater than we initially thought, as standards are sometimes "freely interpreted" or simply implemented incorrectly. In the simplest case, this concerns reversed signs. In more complicated cases, there are issues with incorrect data types, framed data, rotating IDs, and so on.

PV Yield Forecast

Currently, up to six roof surfaces with different orientations, etc., can be set up to retrieve PV yield forecast data for the upcoming day through the service api.forecast.solar. These data can be used by the Eco mode.

Dynamic Electricity Prices

The number of providers for dynamic electricity tariffs is increasing daily. To support all providers, we have implemented a fully configurable solution. The electricity generation costs, which are identical nationwide, are sourced from the ENTSO-E electricity exchange. Grid fees, taxes, price surcharges, etc., can be flexibly defined depending on the provider. Thus, any dynamic electricity tariff can be configured.

Eco Mode

With the Eco Mode, we offer a new charging mode for electric vehicles. The goal is to charge a vehicle using PV surplus until a specified departure time. If the system detects that the expected PV yields are too low, the cheapest hours of a dynamic electricity tariff are used for charging. Depending on settings and departure times, the PV surplus can be fully utilized automatically in the summer. In winter, with low PV yields, inexpensive electricity costs are used.

All Information for the new WARP3 Charger

Bastian Nordmeyer - 11 months ago

New? Actually, the third generation of our WARP Charger (WARP3 Charger) has been available in our shop since the end of March. We apologize for not sharing this news earlier here on the blog. The success of the new wallbox generation caught us off guard, and we simply didn’t get around to reporting it. So, here’s a belated but comprehensive update.

With this new wallbox generation, we’ve also revamped the associated online presence: on warp-charger.com, you’ll find a completely new website dedicated to our wallboxes. Additionally, we’ve updated the documentation for the wallbox. Technical information about the API, compatible power meters, etc., can be found on a separate subpage at docs.warp-charger.com.

With WARP3, we’ve implemented your feedback and made several improvements. Below, we’d like to briefly highlight the most important changes compared to WARP2:

- The WARP3 Charger features integrated phase switching. Two 63A contactors are installed, allowing the wallbox to automatically switch to single-phase operation for PV surplus charging, enabling a charging power starting from just 1.4kW.

- The WARP3 Charger Pro now uses a high-quality Eltako power meter, compared to the previously used Eastron power meter. An RGB LED on the front panel visualizes the status of the wallbox.

- Installation has been significantly simplified. We’ve ensured that there is considerably more space for cable management within the wallbox. The power supply line is conveniently connected to a terminal block in all models. The LAN cable is now also connected directly to the controller again, rather than via an adapter cable. Here too, we’ve made sure that there is ample space for all common RJ45 plug types.

- The good things have remained. The WARP3 is still modular, allowing individual parts to be replaced. The housing has also been retained, so the durable and handy polyester casing is still in use. Even though it’s technically unnecessary, we continue to use massive 63A contactors to ensure a long service life.

Software Updates

Since our last blog post, a lot has happened on the software front. There have been multiple updates for the WARP3, but of course, we haven’t forgotten about the older generations either.

Power Meter Interfaces

Our wallboxes and the WARP Energy Manager can now read data from power meters, inverters, and battery storage systems. Technically, we treat all of these as power meters since they provide us with performance data and other relevant metrics.

In addition to SunSpec, we now also directly support SMA Speedwire, allowing us to read inverters and power meters via these interfaces. Furthermore, with the latest firmware update, the wallboxes can directly query devices using Modbus TCP. We've created register tables for known devices, so inverters from Victron or Deye, for example, can be easily read. However, you can also create your own Modbus TCP register tables if you want to query a device that we don't yet support. We're working on providing register tables for as many devices as possible so that you can simply select them. We’ve also increased the maximum number of configurable power meters to five for the wallboxes and seven for the Energy Manager.

You can find an overview of compatible power meters here.

Remote Access to the Wallbox

The alpha release for remote access has been published in the forum. Here’s the related blog post with the corresponding firmware.

This feature allows you to access your wallbox remotely via your browser. Unlike solutions from other manufacturers, communication is end-to-end encrypted and does not pass through our server. However, a relay server is required, which we provide via my.warp-charger.com. A detailed technical description can be found in the post on Tinkerunity. We expect to include remote access in an upcoming firmware release soon.

iOS and Android App

We’re currently developing apps for iOS and Android to access the wallboxes. These apps will utilize the remote access mentioned above, making it even more convenient to control the wallboxes.

Dynamic Load Management

After a long wait, it’s finally happening. We’re actively testing this feature and have released a beta version in the forum. After more testing this feature will be soon included in a realese firmware. We invested a lot work to get the load management right and cope with different car behaviours and have implemented special handling to ensure a fair charging. You can read more technical information about it in the charge management documentation.

Automatic Firmware Update

Within the next firmware release there will be that feature that you can press a button and the wallbox will scan for an firmware update. If there is a newer firmware available an automatic update is also possible by pressing another button.

Looking Ahead

Dynamic Electricity Prices & PV Yield Forecasting

We are working on supporting dynamic electricity prices for charging with the wallboxes. This means the wallbox can charge the vehicle when the electricity price is at its lowest. However, this option competes with PV surplus charging. It wouldn’t make sense to charge at 4:00 AM with cheap electricity at 15 cents, only to have the PV system generate enough power at 8:00 AM, allowing for even cheaper charging. For this reason, a PV yield forecast feature will be added, enabling the system to decide whether to wait for PV surplus charging or use the cheaper night-time grid electricity.

WARP Energy Manager 2.0

Our WARP Energy Manager was heavily focused on the WARP2 Charger and specifically designed for external phase switching for that wallbox. This feature is no longer necessary for the WARP3 Charger. With the WARP Energy Manager 2.0, we’ve started work on the second generation. The new Energy Manager will use the same concept but will feature more inputs and outputs. It will be controllable as a managed consumer device under the "§14A EnWG Steuerbare Verbrauchseinrichtungen" regulation. SG-Ready capable heat pumps and other devices can be controlled similarly to the WARP Chargers using PV yield and dynamic electricity prices.

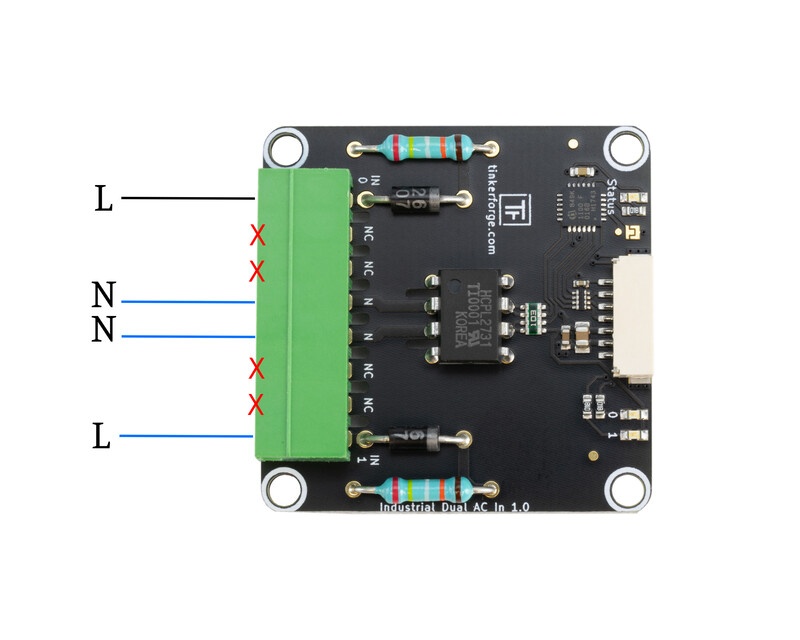

New HAT Brick and Industrial Dual AC In Bricklet

Bastian Nordmeyer - 1 year, 4 months ago

Today we have released version 1.9 of the HAT Brick. This new version is equipped with an improved power supply and can now be operated with an input voltage of 6V-36V. The HAT Brick also supports the power-hungry Raspberry Pi 5.

Additionally, we have released a new Bricklet: The Industrial Dual AC In Bricklet. This Bricklet features two 230VAC-compatible digital inputs. It can be used to monitor two separate 230VAC circuits. Both circuits share a common neutral.