LED display for emergency call center

The integrated control center of the fire department and ambulance service in Brandenburg an der Havel looks after a 5000km² area with a population of 450000. Theys have about 110000 deployments per year.

The control center has 10 dispatcher work places that are occupied depending on the time of day. All of the speech communication (phone as well as analog and digital radio) is done with a Siemens-VASB system.

In the past the shift foreman that was on duty could not easily find out if a dispatcher was currently in a emergency call. After some deliberations it was found out that it was possible to cost effectively solve this problem without any external help by using the Tinkerforge building blocks. A big multicolored LED now shows the status independently for each workplace.

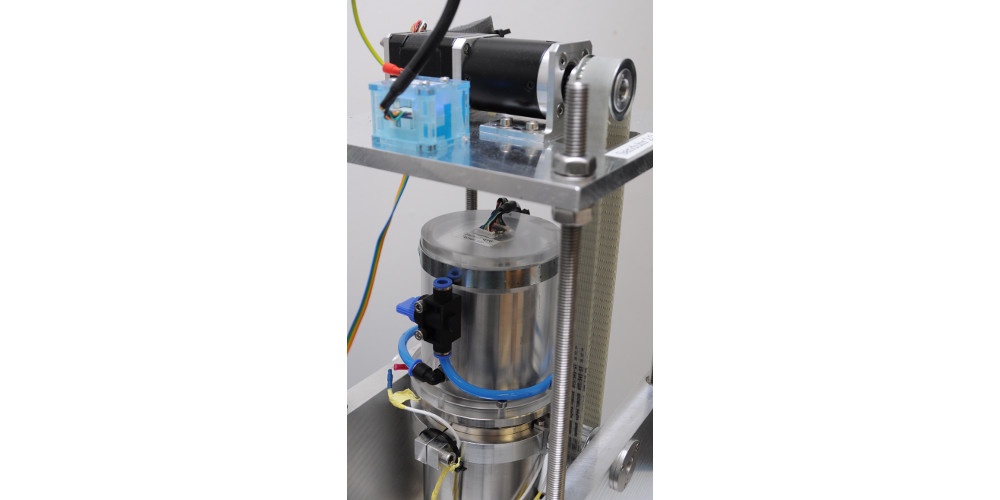

Mobile exhaust measurements

The SESYTEC UG develops measurements, control and automation systems with an emphasis on validation and development of motor and automotive engineering. Currently a mudlar and mobile exhaust measurement system is developed. It can measure CO, CO2, NOx, O2 and HC. Additionally all of the relevant vehicle data are gathered analized and visualized. For the capture of environment data (air pressure, humidity, temperature) a roofbox equiped with Tinkerforge building blocks is used. The box is connected through Ethernet and it can be extended with thermocouples for measurements of part and gas temperatures.

Dependent on the task it is possible to use the system in a vehicle or on a test bench. The software uses a mix of LabView, JavaScript and Python to implement a user oriented interface. Tinkerforge offers a platform that is perfectly suited to build this kind of system rapidly. By default all of the functionality is provided through the integrated web interface. More information is available here.

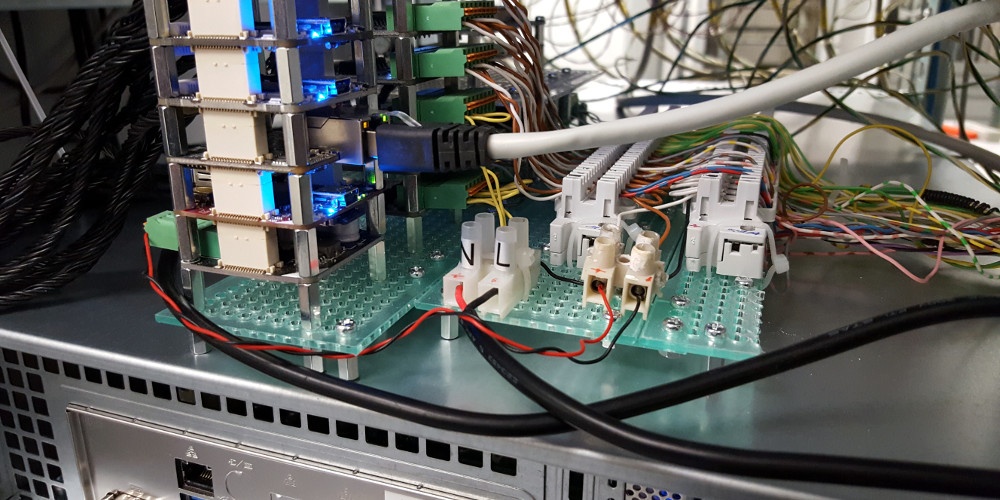

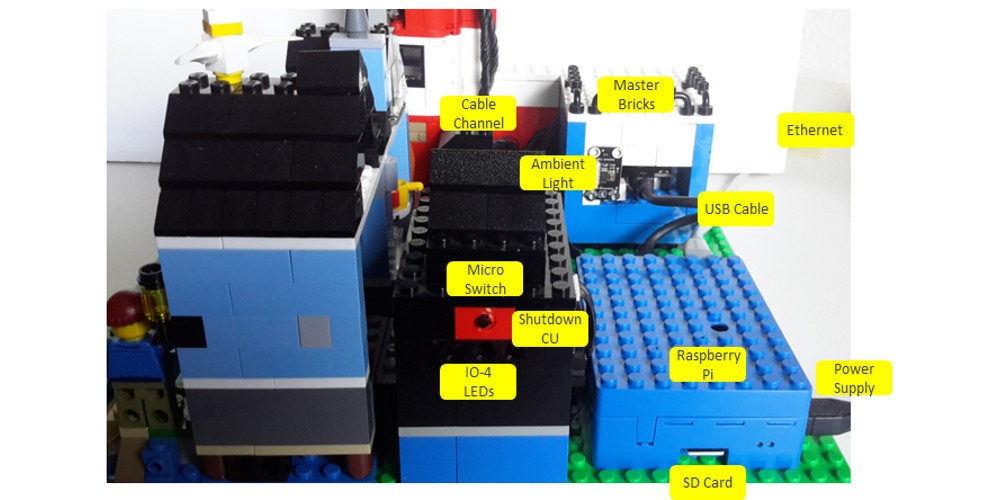

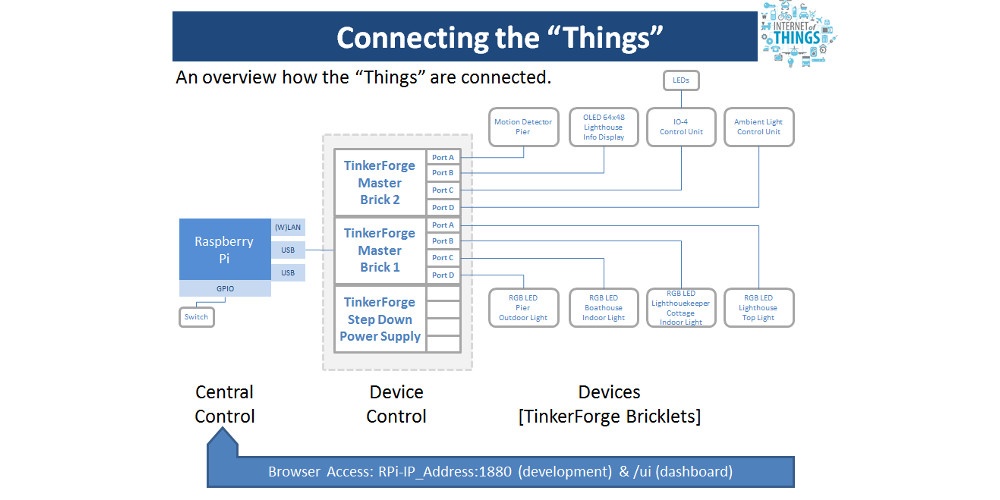

IoT Learning Case

Lighthouse58 is an Internet of Things learning case based upon the LEGO® Lighthouse Point 31051. The goal was to enhance the features of the Lighthouse by integrating and controlling devices, e.g. top light, OLED display with a clock & actual weather (at the Lighthouse position gathered from Weather Underground), motion detector, outdoor lights, room lights, lights dimming, ambient light, LEDs. Its original build has been enhanced to accommodate the various devices. In addition a newly designed Control Unit holds the controllers. Controlled by a Raspberry Pi with TinkerForge Master Bricks & Bricklets. Communication between the controller and the devices is done via MQTT (TinkerForge Brick MQTT Proxy). A browser based Node-RED Dashboard (included in Raspberry Pi OS Raspbian Jessie) controls the devices, but any MQTT client can be used to access & control Lighthouse58.

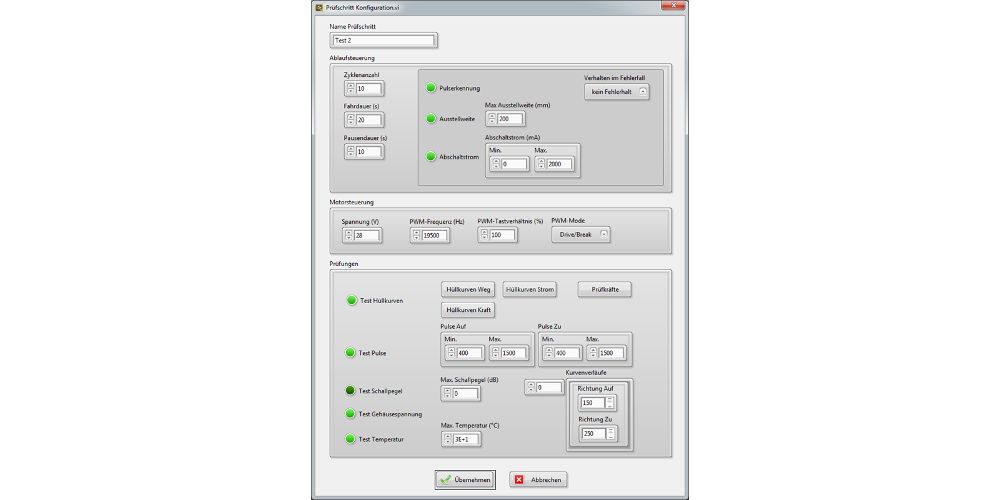

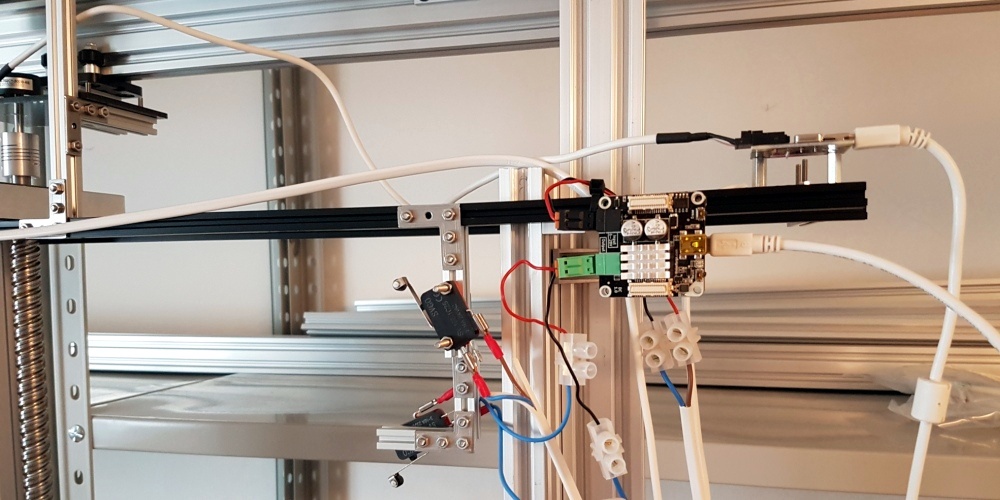

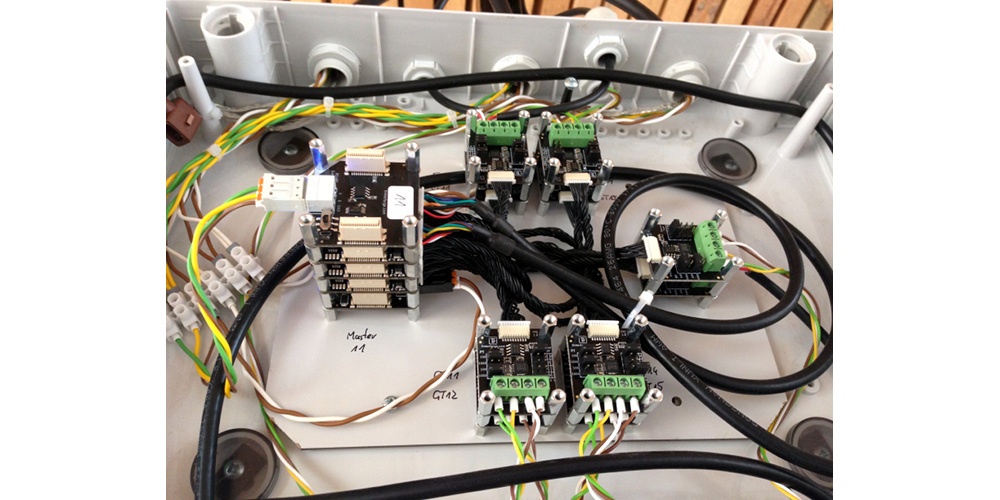

Test station for automated endurance testing of window actuators

The company STG-BEIKIRCH is a system partner of the ESSMAN GROUP. It is specialized the domains facade and building automation as well as industrial electronics. They are a leading manufacturer of smoke and heat extraction systems.

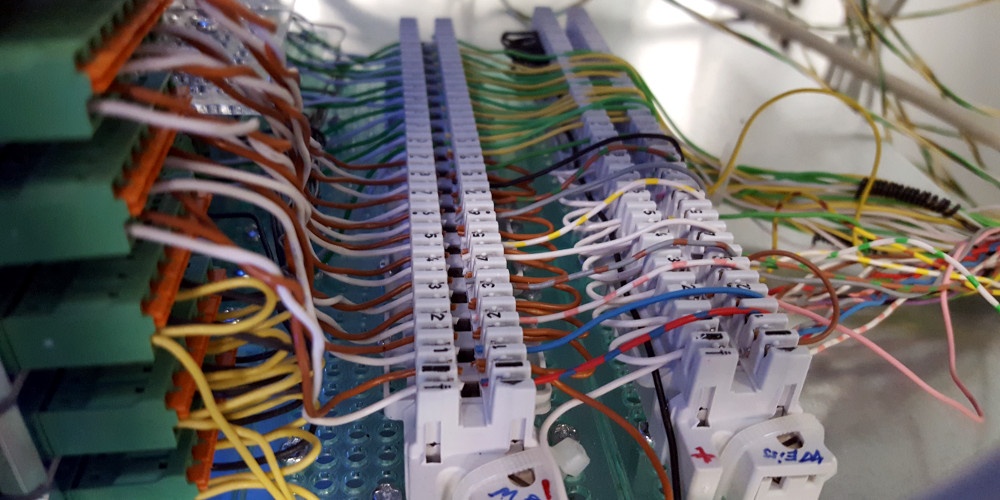

With the help of many years of experience a new generation of test stations were developed. One of the test stations is used to put drives under electronical and mechanical function tests. How much current is needed, what tractive force is required, how loud is the drive? Is the target position reached? Is the specified temperature range complied with?

It do the automatic endurance tests for two drives at the same time. Through a software (created with the graphical programming langauges LabVIEW) the testing parameters are entered. The parameters include distance, current, force, voltage, case voltage, temperature, loudness and motor pulse. The tests runs through 10000 to 20000 cycles, which corresponds to a test time of several weeks. During the testing all of the specified values are monitored and the test data is saved.

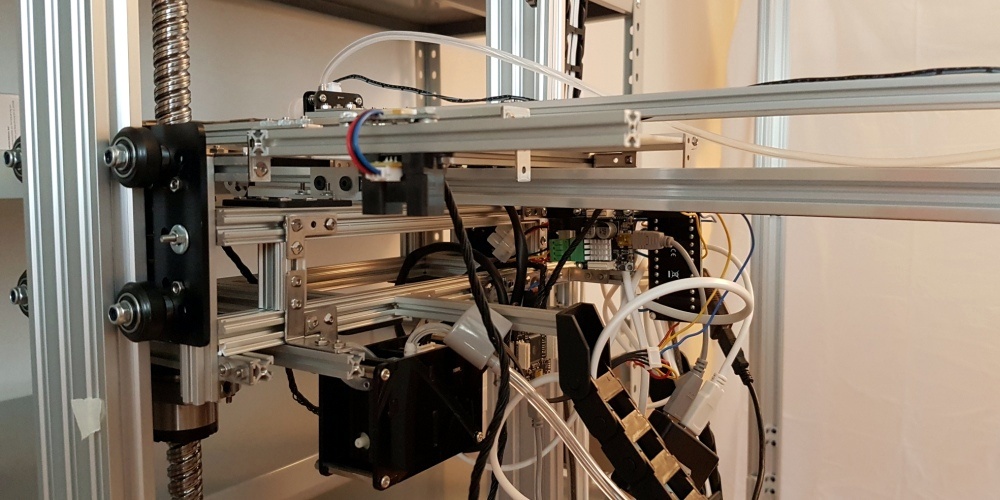

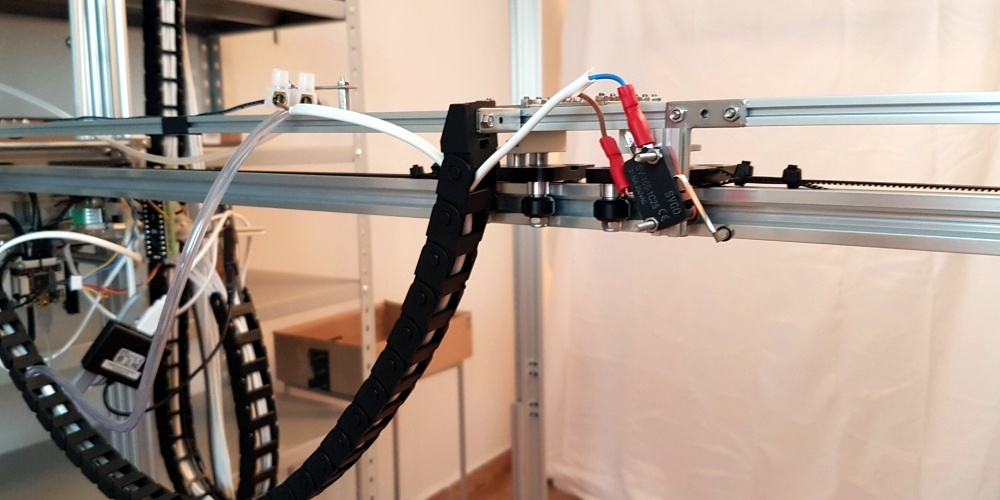

Automated warehouse

The Italian company ValeProg develops a prototype for a automated warehouse. It uses a 3-axis gripper to take stock from the shelfs and put stock into the shelfs. The hardware uses two Stepper Bricks and one DC Brick. It is controlled through USB. Compared to standard automation solutions the hardware only costs a fraction.

Sensor system for electric car charging station

EnBW is developing the inteligent street light of tomorrow: Smart City Light (SM!GHT). It comes as a charing station with sensor system.

The foundation of the system is provided by the Tinkerforge building blocks.

Switchable info terminal

Independent control of industry PCs and touch screen monitors with Dual Relay Bricklet, Master Brick and Raspberry Pi.

The university for soil culture has info terminals that can be used by visitors, students and employees to gain information about the university as well as lecture dates and content. Additionally it is possible for students and employees to start print jobs. The infor terminals run on free software in a self-developed kiosk mode that is catered to the needs of BOKU. The Tinkerforge components are used for remote power management. To save energy, the terminals are automatically turned off when they are not used.

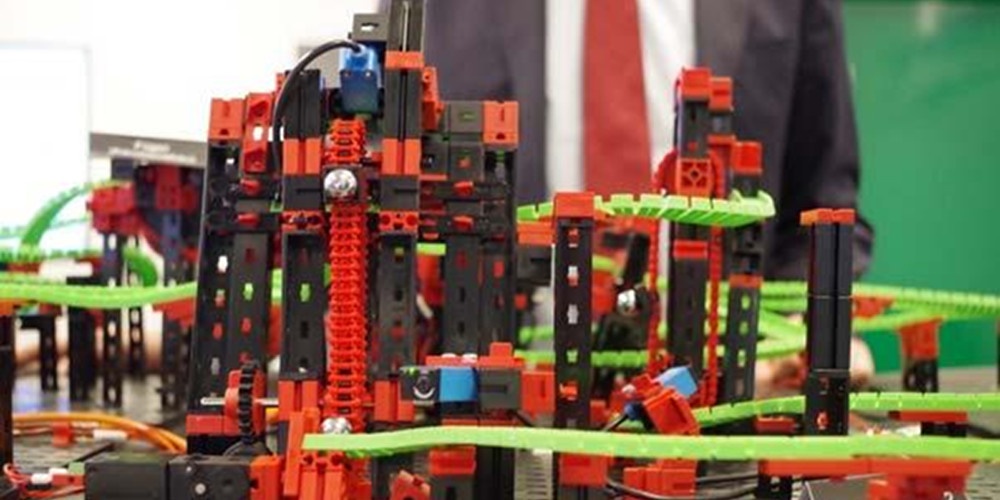

Ball Demonstrator

At the core of the logistics demonstrator of the RWTH Aachen is a ball run that illustrates the production of the Demofabrik Aachen (DFA). This model factory originated in in the research project "ProSense". The aim of this research project is to develop a high-resolution, adaptive production control based on cybernetic support systems and intelligent sensors. One run of the ball represents the processing of production order in the factory. The different manufacturing stages are represented by vertical transport routes. The routes between two machines are represented by the path of the ball. This model allows for a better understanding of production processes and to find and fix problems. The model is also interesting for the research of the FIR, since it allows to test the research case scenarios at a small scale with a realistic modeling that can be transferred to a real production line.

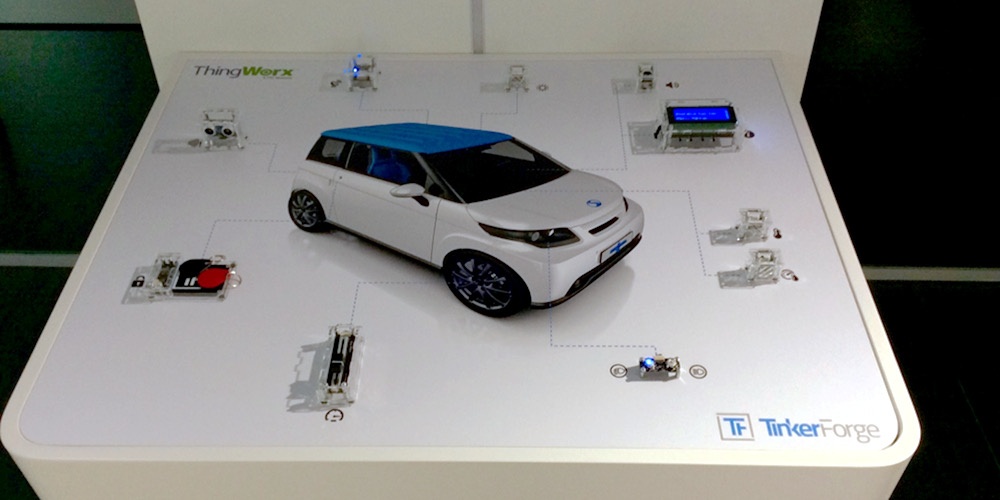

IoT Demonstrator: "Thing Case"

The company PTC uses the Tinkerforge building blocks for different applications. One application is the ThingWorx IoT-Platform that is shon in the RWTH Aachen. This demonstrator shows the principles of IoT in an easy to understand manner. It shows examples of the electric vehicle project "StreetScooter" within in the scope of connected cars.

PTC also uses the building blocks in combination with the ThingWorx IoT-Platform for customer specific presentations to show industrial processes on a small scale. The processes are simulated which allows to showcase the performance of the software.

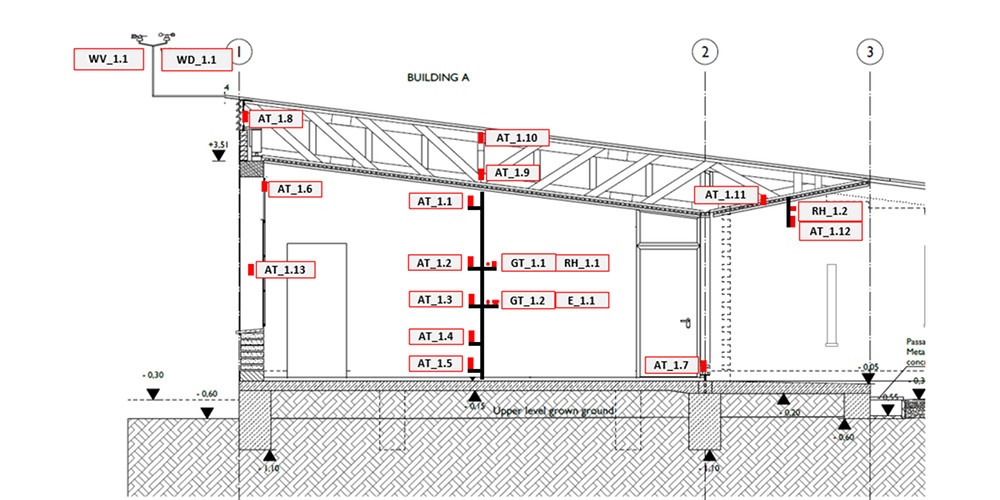

Sustainable School Building in Zambia

The government in Zambia started an education initiative in 2013 with the goal to construct 10000 new classrooms. As an alternative to standard school buildings the Ministry of Education in Zambia is looking at a new concept that was developed by engineers and architects of the Technischen Universität München (TUM): "Green School Zambia".

The goal of the project is the development of school buildings for Zambia that can be deployed in the whole country. The current focus is on a prototypical school and the international transfer of knowledge between TU München and the University of Zambia (UNZA). The prototype works as a isolated application that can be used in less developed and rural areas. It is optimized for improved resource allocation, indoor climate, energy supply and sanitation.

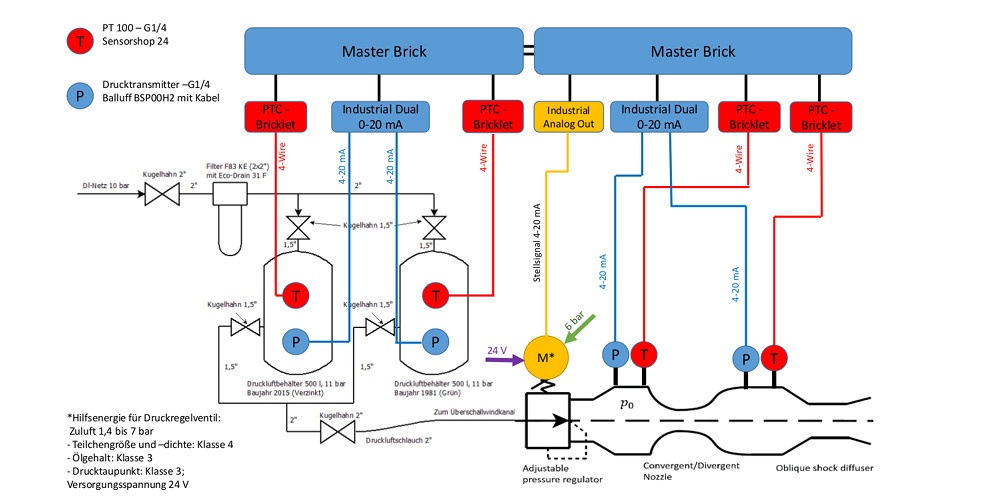

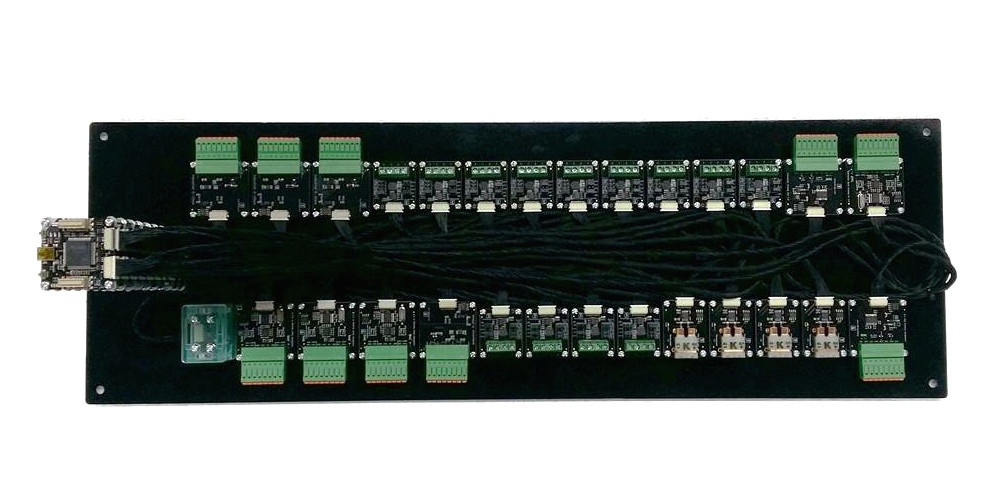

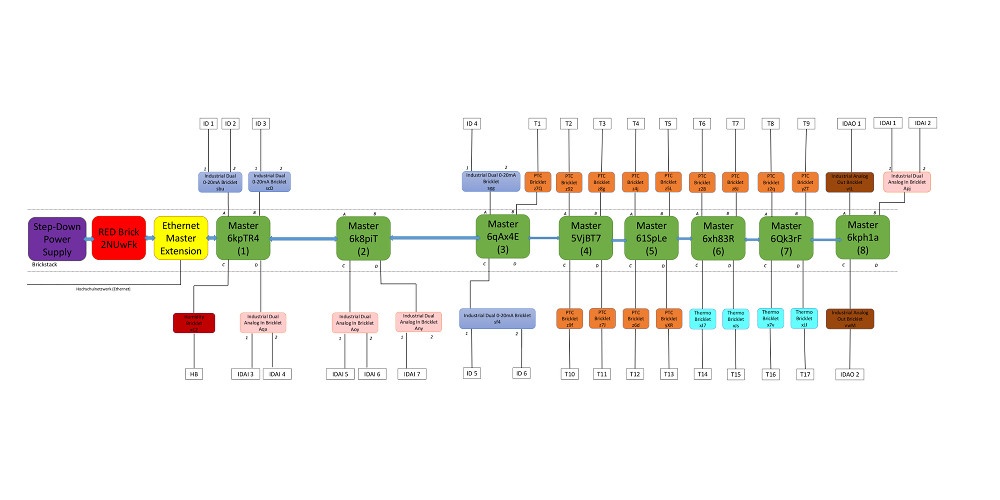

Supersonic Windtunnel

The University of Coburg has a supersonic wind tunnel used for research. The wind tunnel is operated by compressed air tanks and it is controlled by the Tinkerforge building blocks. Different sensors determine the state of the system and allow for the analysis of experiments.

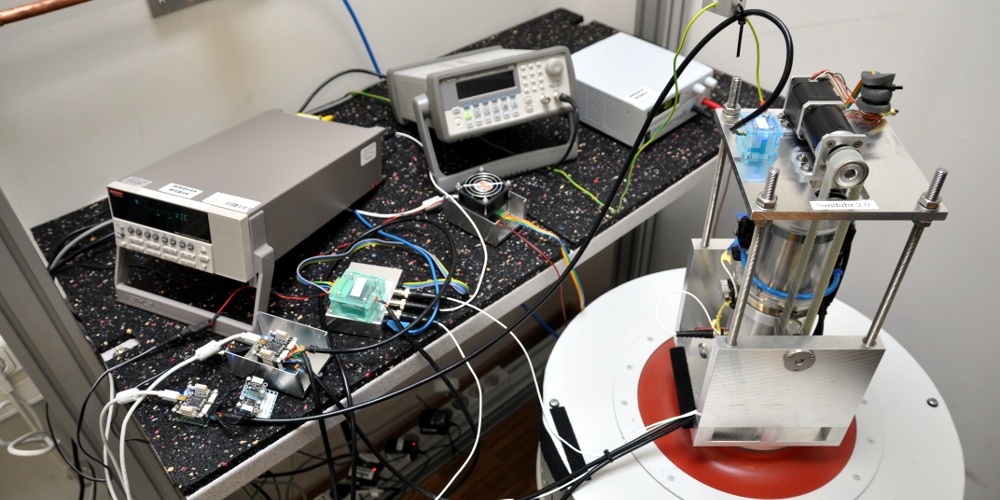

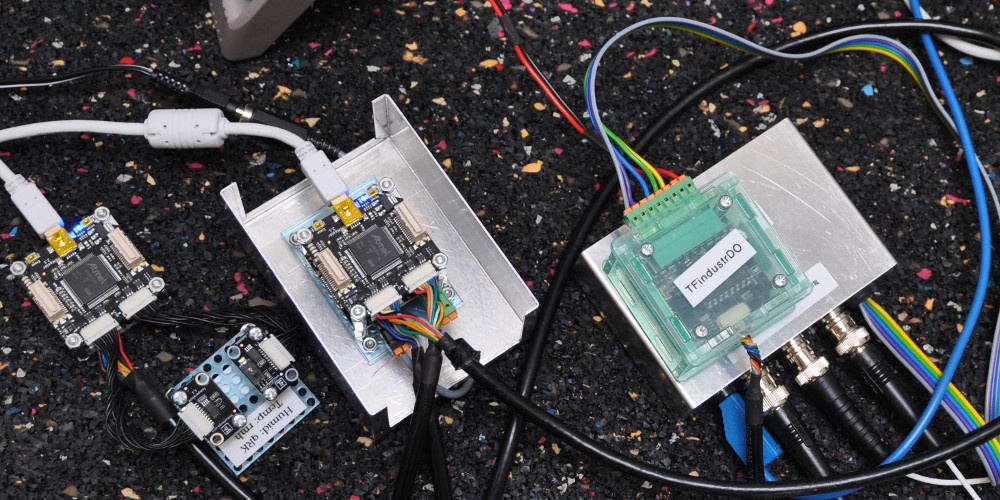

Charge Measurement in Granular Media

The Max-Planck Institut for Dynamics und Self-Organization in Göttingen investigates physical mechanisms that lead to self-organization in complex systems. Examples are active swimmers, bacterial colonies or charged granular particles. The “rotating cup” is used for charge measurements of agitated granular media. It is a combination of granulate container and Faraday cup that is mounted on an electromagnetic shaker.

During the development phase of the setup the simple control of the individual components as well as a high degree of automation have been important. The building blocks from Tinkerforge are integrated through a LabVIEW user interface. The experiment can measure charges with a high quality (read more here).