- Getting Started

- Hardware

- Bricks

- Bricklets

- Accelerometer Bricklet 2.0

- Air Quality Bricklet

- Ambient Light Bricklet 3.0

- Analog In Bricklet 3.0

- Analog Out Bricklet 3.0

- Barometer Bricklet

- Barometer Bricklet 2.0

- Breakout Bricklet

- CAN Bricklet

- CAN Bricklet 2.0

- CO2 Bricklet 2.0

- Color Bricklet

- Color Bricklet 2.0

- Compass Bricklet

- DC Bricklet 2.0

- Distance IR Bricklet

- Distance IR Bricklet 2.0

- Distance US Bricklet 2.0

- DMX Bricklet

- Dual Button Bricklet 2.0

- Dust Detector Bricklet

- E-Paper 296x128 Bricklet

- Energy Monitor Bricklet

- GPS Bricklet 2.0

- GPS Bricklet 3.0

- Hall Effect Bricklet

- Hall Effect Bricklet 2.0

- Humidity Bricklet 2.0

- IMU Bricklet 3.0

- Industrial Analog Out Bricklet 2.0

- Industrial Counter Bricklet

- Industrial Digital In 4 Bricklet 2.0

- Industrial Digital Out 4 Bricklet

- Industrial Digital Out 4 Bricklet 2.0

- Industrial Dual 0-20mA Bricklet

- Industrial Dual 0-20mA Bricklet 2.0

- Industrial Dual AC In Bricklet

- Industrial Dual AC Relay Bricklet

- Industrial Dual Analog In Bricklet 2.0

- Industrial Dual Relay Bricklet

- Industrial PTC Bricklet

- Industrial Quad Relay Bricklet 2.0

- IO-16 Bricklet

- IO-16 Bricklet 2.0

- IO-4 Bricklet 2.0

- Isolator Bricklet

- Joystick Bricklet

- Joystick Bricklet 2.0

- Laser Range Finder Bricklet 2.0

- LCD 128x64 Bricklet

- LCD 20x4 Bricklet

- LED Strip Bricklet 2.0

- Line Bricklet

- Linear Poti Bricklet

- Linear Poti Bricklet 2.0

- Load Cell Bricklet 2.0

- Motion Detector Bricklet 2.0

- Motorized Linear Poti Bricklet

- Multi Touch Bricklet

- Multi Touch Bricklet 2.0

- NFC Bricklet

- OLED 128x64 Bricklet 2.0

- OLED 64x48 Bricklet

- One Wire Bricklet

- Outdoor Weather Bricklet

- Particulate Matter Bricklet

- Performance DC Bricklet

- Piezo Speaker Bricklet

- Piezo Speaker Bricklet 2.0

- Real-Time Clock Bricklet

- Real-Time Clock Bricklet 2.0

- Remote Switch Bricklet 2.0

- RGB LED Bricklet 2.0

- RGB LED Button Bricklet

- Rotary Encoder Bricklet 2.0

- Rotary Poti Bricklet

- Rotary Poti Bricklet 2.0

- RS232 Bricklet

- RS232 Bricklet 2.0

- RS485 Bricklet

- Segment Display 4x7 Bricklet

- Segment Display 4x7 Bricklet 2.0

- Servo Bricklet 2.0

- Silent Stepper Bricklet 2.0

- Solid State Relay Bricklet 2.0

- Sound Intensity Bricklet

- Sound Pressure Level Bricklet

- Temperature Bricklet

- Temperature Bricklet 2.0

- Temperature IR Bricklet 2.0

- Thermal Imaging Bricklet

- Thermocouple Bricklet 2.0

- Tilt Bricklet

- UV Light Bricklet 2.0

- Voltage/Current Bricklet 2.0

- XMC1400 Breakout Bricklet

- Master Extensions

- Power Supplies

- Discontinued Products

- Timeline

- Software

- Kits

- Embedded Boards

- Specifications

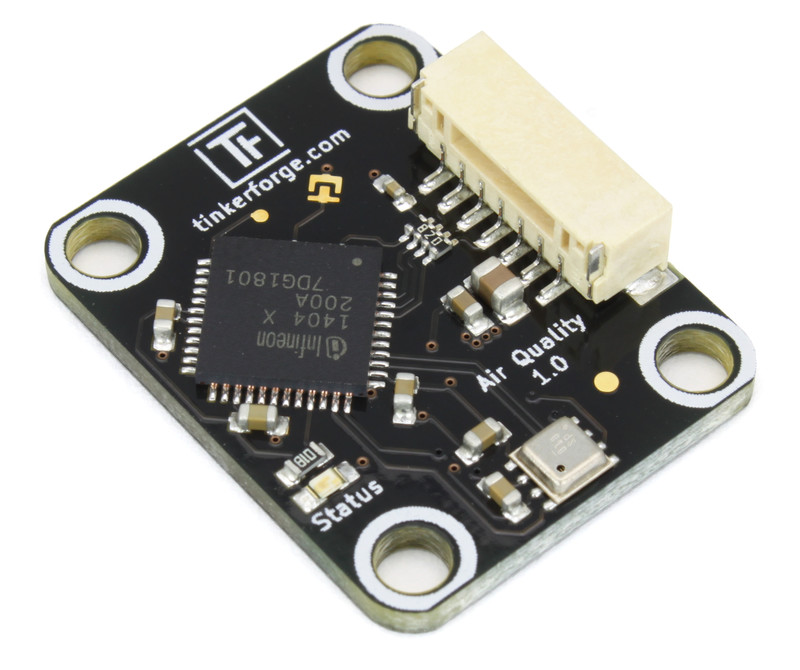

Air Quality Bricklet¶

Features¶

Measures IAQ (indoor air quality) index, air pressure, humidity and temperature

IAQ index and humidity values are temperature compensated

Configurable temperature compensation for use cases in enclosures

Description¶

The Air Quality Bricklet can measure

IAQ (indoor air quality) index,

Air pressure in hPa,

Humidity in %RH and

Temperature in °C.

The IAQ index is a measurement for the quality of air. To calculate the IAQ index the Bricklet detects ethane, isoprene (2-methylbuta-1,3-diene), ethanol, acetone and carbon monoxide (often called VOC, volatile organic components) by adsorption. These gas measurements are combined with the measurements of air pressure, humidity and temperature to calculate the final IAQ index.

The IAQ index has a range of 0-500:

Typical applications for this Bricklet are the monitoring of air quality, environmental statistics, home automation and similar.

Technical Specifications¶

Property |

Value |

|---|---|

Sensor |

BME680 |

Current Consumption |

100mW (20mA at 5V) |

IAQ Index Resolution |

1 |

Air Pressure Resolution |

0.0018hPa |

Humidity Resolution |

0.008%RH |

Temperature Resolution |

0.01°C |

IAQ Index Accuracy |

±15 and ±15% of reading |

Air Pressure Accuracy |

±0.12hPa (700-900hPa at 25-40°C), ±0.6hPa (full scale) |

Humidity Accuracy |

±3%RH (20-80%RH at 25°C) |

Temperature Accuracy |

±0.5°C (at 25°C), ±1.0°C (0-65°C)* |

Measurement Frequency |

0.3 measurements per second |

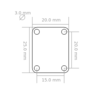

Dimensions (W x D x H) |

25 x 20 x 5mm (0.98 x 0.79 x 0.19") |

Weight |

2.1g |

* This is the temperature at the exact position of the sensor. If the Bricklet is used inside of an enclosure, the air around the Bricklet may heat up more than the ambient air. The Bricklet does have API to calibrate this kind of offset.

Calibration of the temperature value is recommended, since the temperature value is used to compensate the IAQ index and humidity values.

Resources¶

IAQ Accuracy and Automatic Calibration¶

The Bricklet is building a database of measurements and uses this data to do an automatic background calibration and calculate an accurate IAQ index over time. It will take a few days until the IAQ index has a high reliability.

The IAQ accuracy is reflects the current state of the background calibration process.

Accuracy 0: The Bricklet was just started and the sensor is stabilizing.

Accuracy 1: The background history is uncertain. This typically means the gas sensor data was too stable for the calibration algorithm to clearly define its references.

Accuracy 2: The Bricklet found new calibration data and is currently calibrating.

Accuracy 3: The Bricklets is calibrated successfully.

The effective duration of the calibration process depends on the stimuli observed by the sensor. An IAQ accuracy going back and fourth between 2 and 3 is expected, the Bricklet is recalibrating itself.

The Bricklet saves the current database of values and calculated coefficients every 12 hours in its internal flash memory. If the Bricklet loses power it will not take as long to receive reliable data again.

Starting with firmware version 2.0.3 the automatic background calibration considers 28 days of data. We recommend that you run the Bricklet for 28 full days before you consider the data as completely reliable. It is possible to reduce the calibration window to 4 days with the API.

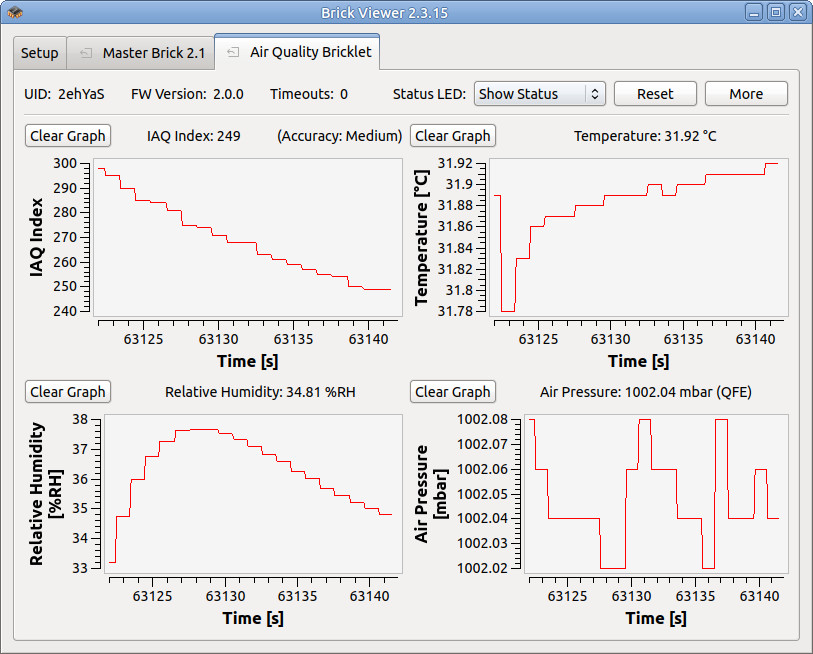

Test your Air Quality Bricklet¶

To test a Air Quality Bricklet you need to have Brick Daemon and Brick Viewer installed. Brick Daemon acts as a proxy between the USB interface of the Bricks and the API bindings. Brick Viewer connects to Brick Daemon. It helps to figure out basic information about the connected Bricks and Bricklets and allows to test them.

Connect the Air Quality Bricklet to a Brick with a Bricklet Cable.

If you connect the Brick to the PC over USB, you should see a new tab named "Air Quality Bricklet" in the Brick Viewer after a moment. Select this tab. If everything went as expected you can now see the values for IAQ index, air pressure, humidity and temperature.

After this test you can go on with writing your own application. See the Programming Interface section for the API of the Air Quality Bricklet and examples in different programming languages.

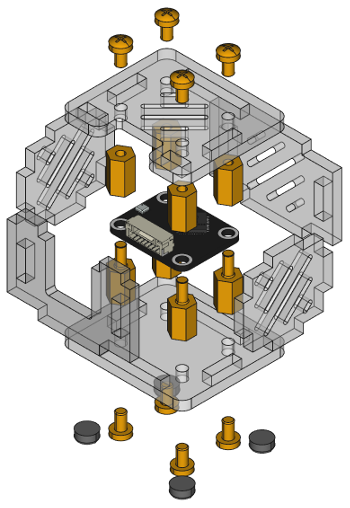

Case¶

A laser-cut case for the Air Quality Bricklet is available.

The assembly is easiest if you follow the following steps:

Screw spacers to the Bricklet,

screw bottom plate to bottom spacers,

build up side plates,

plug side plates into bottom plate and

screw top plate to top spacers.

Below you can see an exploded assembly drawing of the Air Quality Bricklet case:

Hint: There is a protective film on both sides of the plates, you have to remove it before assembly.

Programming Interface¶

See Programming Interface for a detailed description.

Language |

API |

Examples |

Installation |

|---|---|---|---|

C/C++ |

|||

C/C++ for Microcontrollers |

|||

C# |

|||

Delphi/Lazarus |

|||

Go |

|||

Java |

|||

JavaScript |

|||

LabVIEW |

|||

Mathematica |

|||

MATLAB/Octave |

|||

MQTT |

|||

openHAB |

|||

Perl |

|||

PHP |

|||

Python |

|||

Ruby |

|||

Rust |

|||

Shell |

|||

Visual Basic .NET |

|||

TCP/IP |

|||

Modbus |